4V/292 filter element for GAS TURBINE sector, fully burnable, without any toxic gas emission.

Filter medium: glass fiber, water repellency treatment and dual layer renforced structure standard and energy save (30%) versions.

Separators: automatic dispensing of thermoplastic wires (minipleat technique), which allow to optimize air flow, maintaning a constant pitch between pleats through their depth.

Frame: self-draining in MOPLEN (PPE), higher tensilen strength, lower density, higher termic resistance, higher abrasion resistance than polystyrene frames.

Sealing system: hard PUR automatically dispensed inside V elements and in side frame.

Outer protection grids: moulded HD polyethylene on all minipleat panels air outlet side (clean side).

Gasket: seamless type in semiexpanded PUR automatically dispensed.

| UNI EN 779:2012 class | F9 |

| EUROVENT class | EU9 |

| Average efficiency at 0,4 μm | 95% < Em |

| Frame colour | Black & Red |

| Dimensions | 592x592x292 mm |

| Filtering surface | 20 m² |

| Initial pressure drop | |

| Nominal air flow 3400m³/h | 118 Pa |

| Nominal air flow 4250m³/h | 160 Pa |

| Final recommended pressure drop | |

| Nominal air flow 3400m³/h | 650 Pa |

| Nominal air flow 4250m³/h | |

| Burst strength | 5000 Pa |

| Max working temperature | 70° C |

| Max working relative humidity | 100% |

| Regenerability | NO |

Fully potted by PUR

Outer protection grids fon all minipleat panels in moulded HD polyethylene

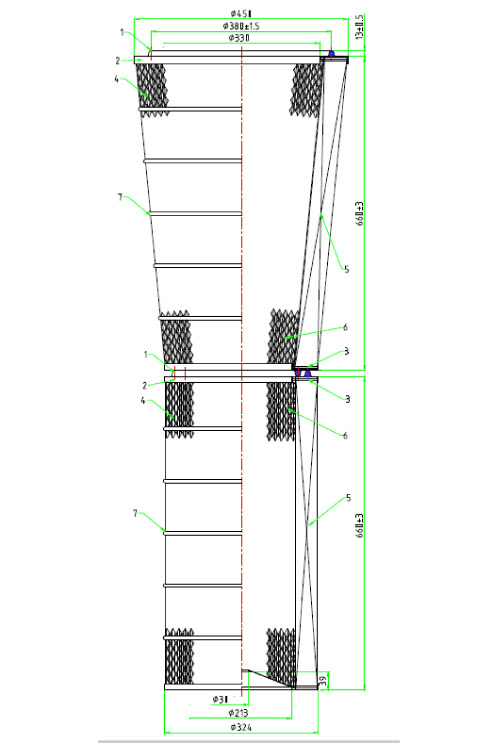

1. Gaskets: Semi-expanded PUR seamless type

2. Upper flanges and bottom ends: epoxy grey painted steel 8/10.

3. Sealant: hard neutral PU.

4. Outer liner: expanded galvanised steel, rhomboidal mesh 20x10 mm, feed 1,5mm, thickness 8/10.

5. Filtering media: pleated media composed by blend of cellulose and synthetic fibres (80/20) with a surface treatment of nano fibers, our ref. M92NF, resistant to humidity and to solicitations of pulse-jet counter flow compressed air, expressly studied for gas turbines applications. This filter media fulfil dust class M according to DIN EN 60335-2-69 annex AA and class efficiency F9 according to EN779:2012

6.Inner liner: expanded galvanised steel, romboidhal mesh 20x10 mm, feed 1,5mm, thickness 8/10.

7. Pleat lock system: automatic dispensing of n° 5 hot-melt bands and pitch maintenance through “dimple pleat” system.

| Reference | TS1553/12NF | TS1553/13NF | |

| UNI EN779:2012 Class | F9 | ||

| EUROVENT Class | EU9 | ||

|

UNI 10339 efficiency prosp.V (atmospheric test method) |

Em≤95% | ||

| ASHRAE Class | MERV 15 | ||

| Height | 660 mm | 660 mm | |

| Top flange dimensions | DE450 mm DI330 mm | DE324 mm DI213 mm | |

| Bottom end dimensions | DE324 mm DI213 mm | DE324 mm F30 mm | |

| Gasket sealing diameter top side | 420 mm | 278 mm | |

| Gasket sealing diameter bottom side | 242 mm | none | |

| Filter Area | 23 m2 | 21 m2 | |

| Number of pleats | 357 | 326 | |

| Initial pressure drop | 163 Pa | ||

| Nominal air flow | 2500 m3/hEm≤95% | ||

| Max working temperature | 80 °C | ||

| Max. working RH | 90% |